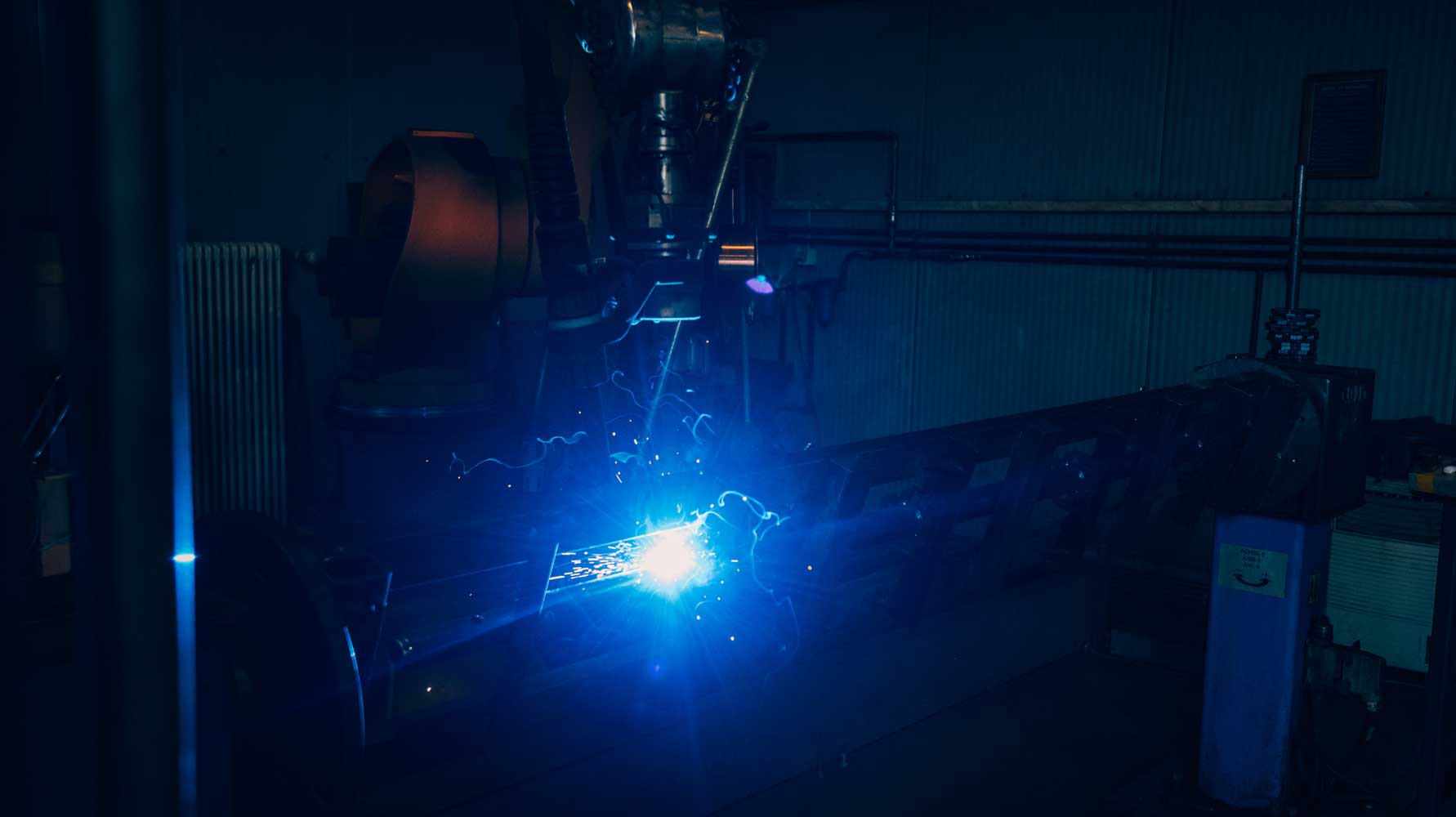

ROBOT AND MANUAL WELDING

Thanks to our well-trained, highly experienced welders, we are able to provide optimal manufacturing performance and quality. Our team is specialised to weld stainless steel, carbon steel and aluminium elements. Our colleagues take part in training courses organised by our company, and we continuously develop our tools according to our opportunities, and this way, we are able to keep up with technological advances.

Our equipment includes the following:

-27 manual welding stations, suitable for MIG-MAG welding

– 1 robot welding station

– 1 spot welding station

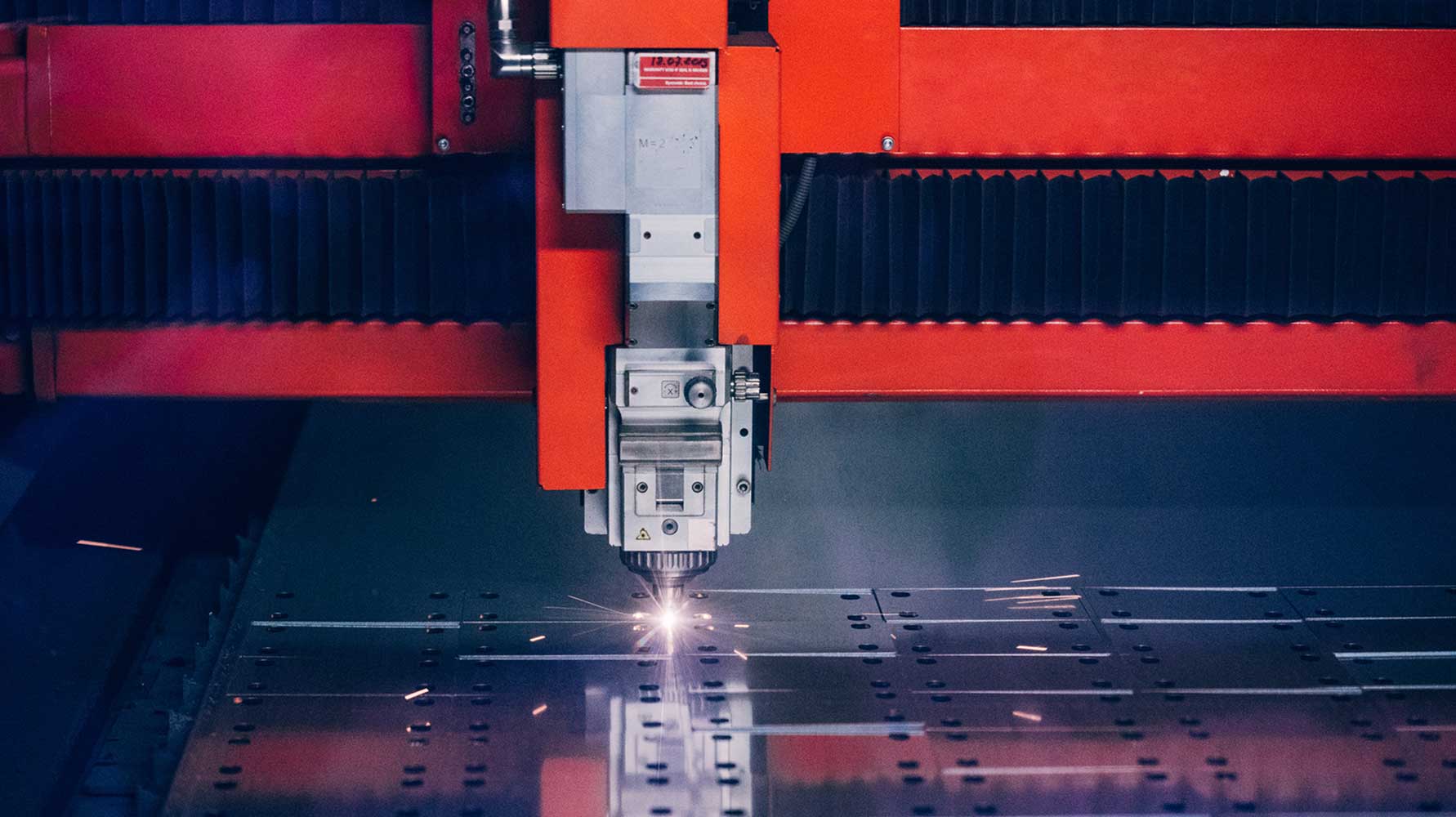

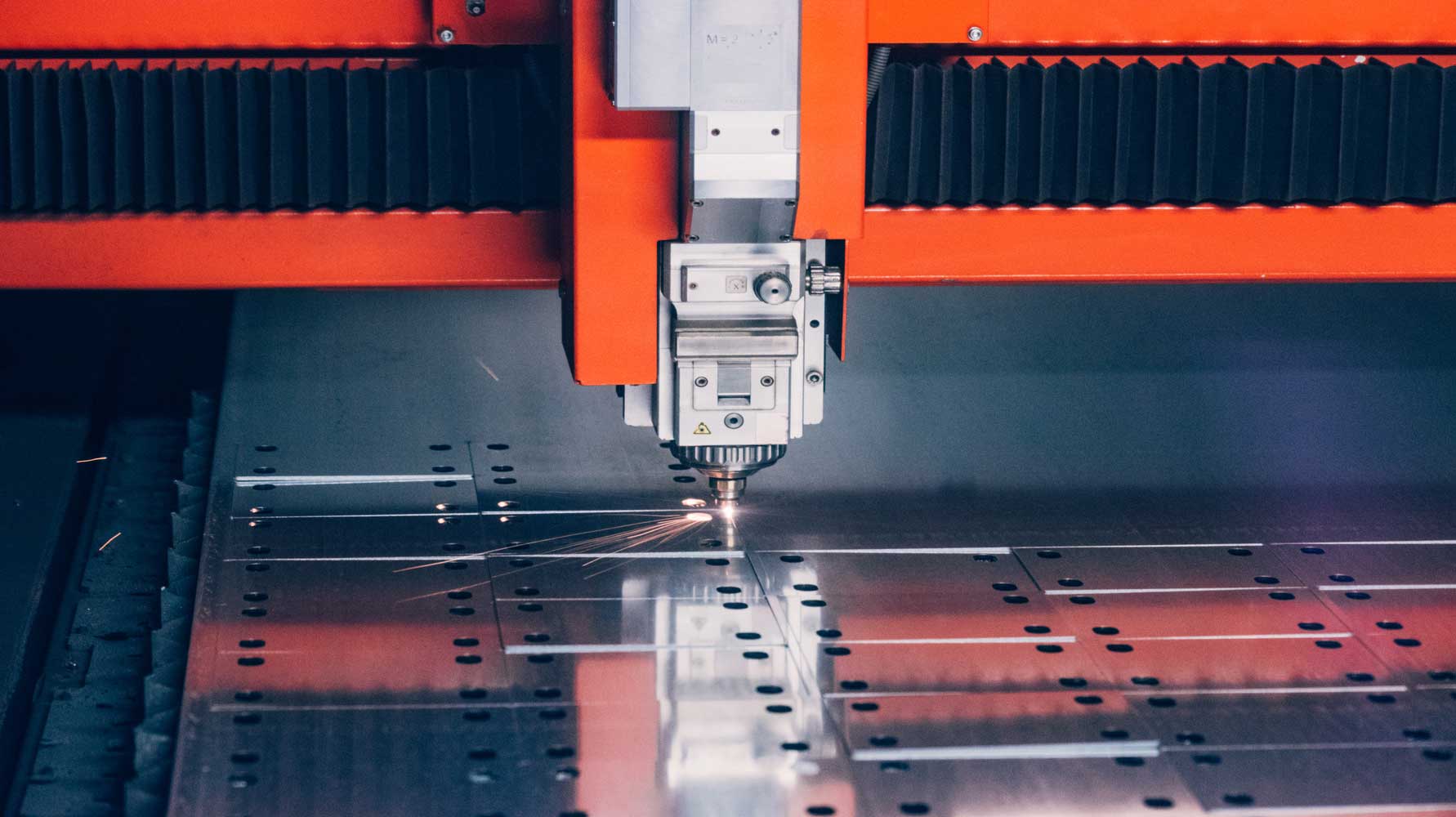

LASER AND PLASMA CUTTING

Thanks to our computer-controlled plasma and laser cutting equipment, we can provide our clients with fast and precise sheet cutting, be it for unique pieces or large orders. According to our clients’ requests, we handle cross cutting and complete processing, depending on the products’ production technology requirements.

Plasma cutter:

-ESAB COMBIREX 2500 – DX3000 – 1 piece

Laser cutter:

-BYSTRONIC 3015 – 1 piece

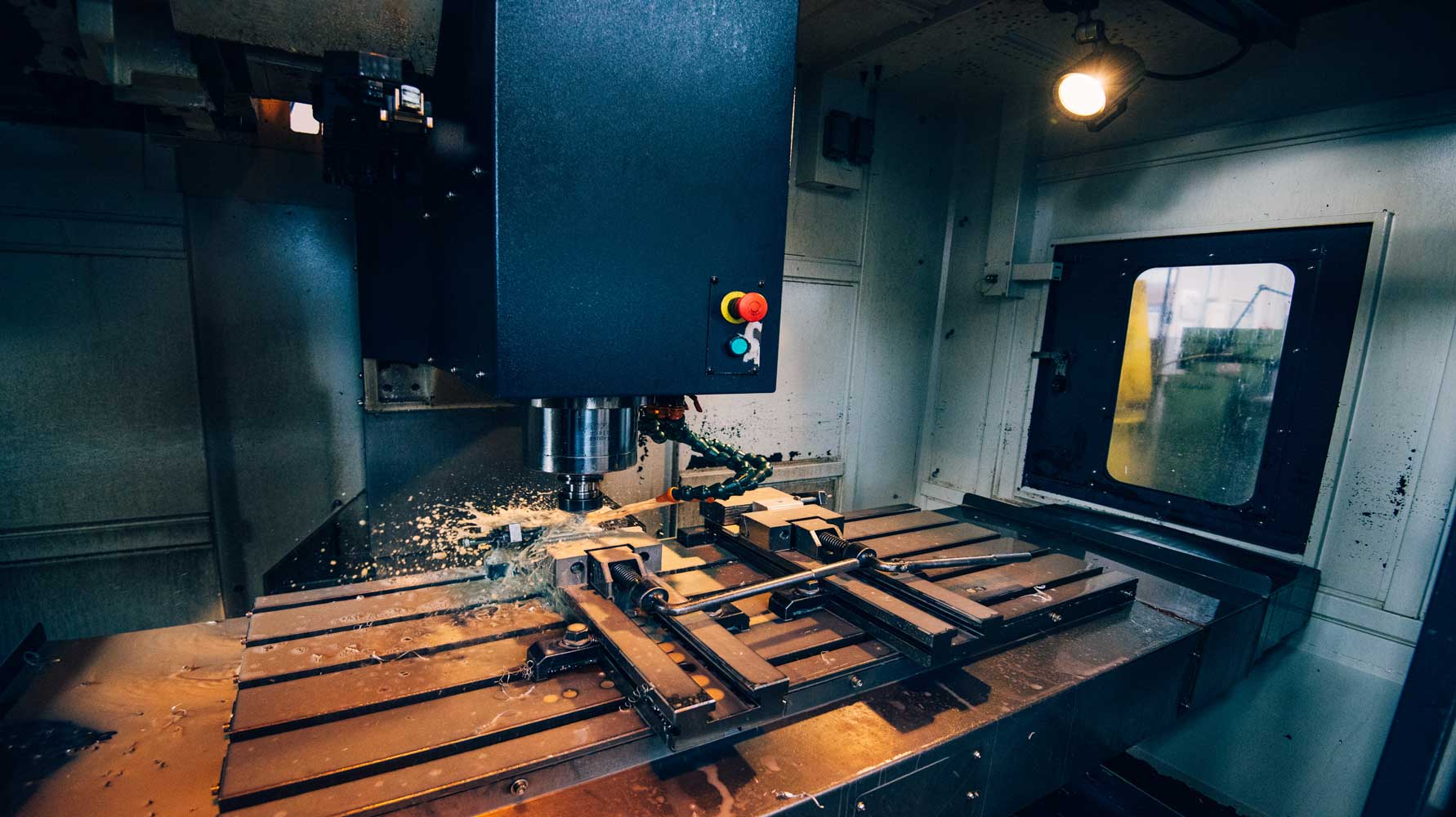

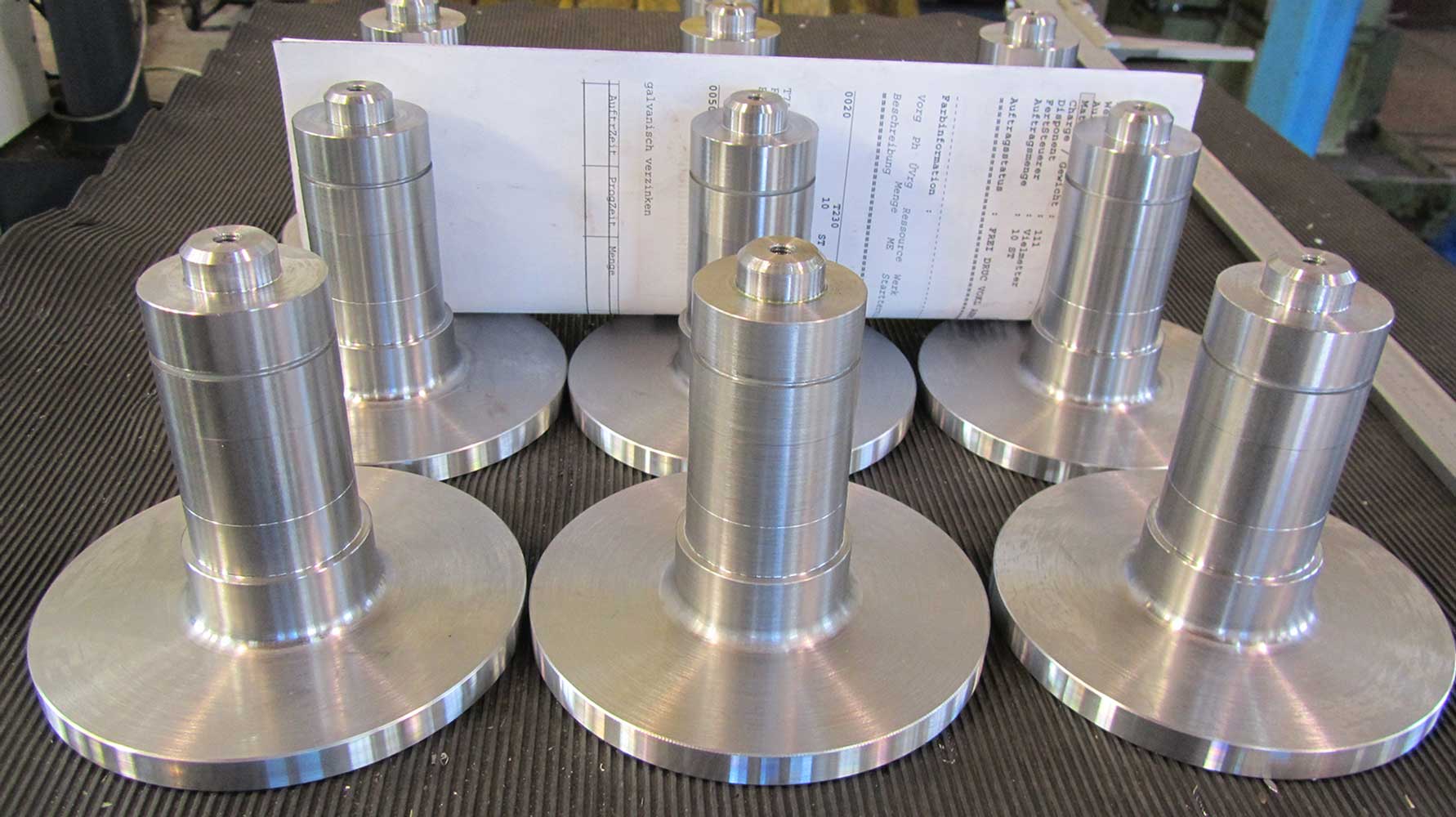

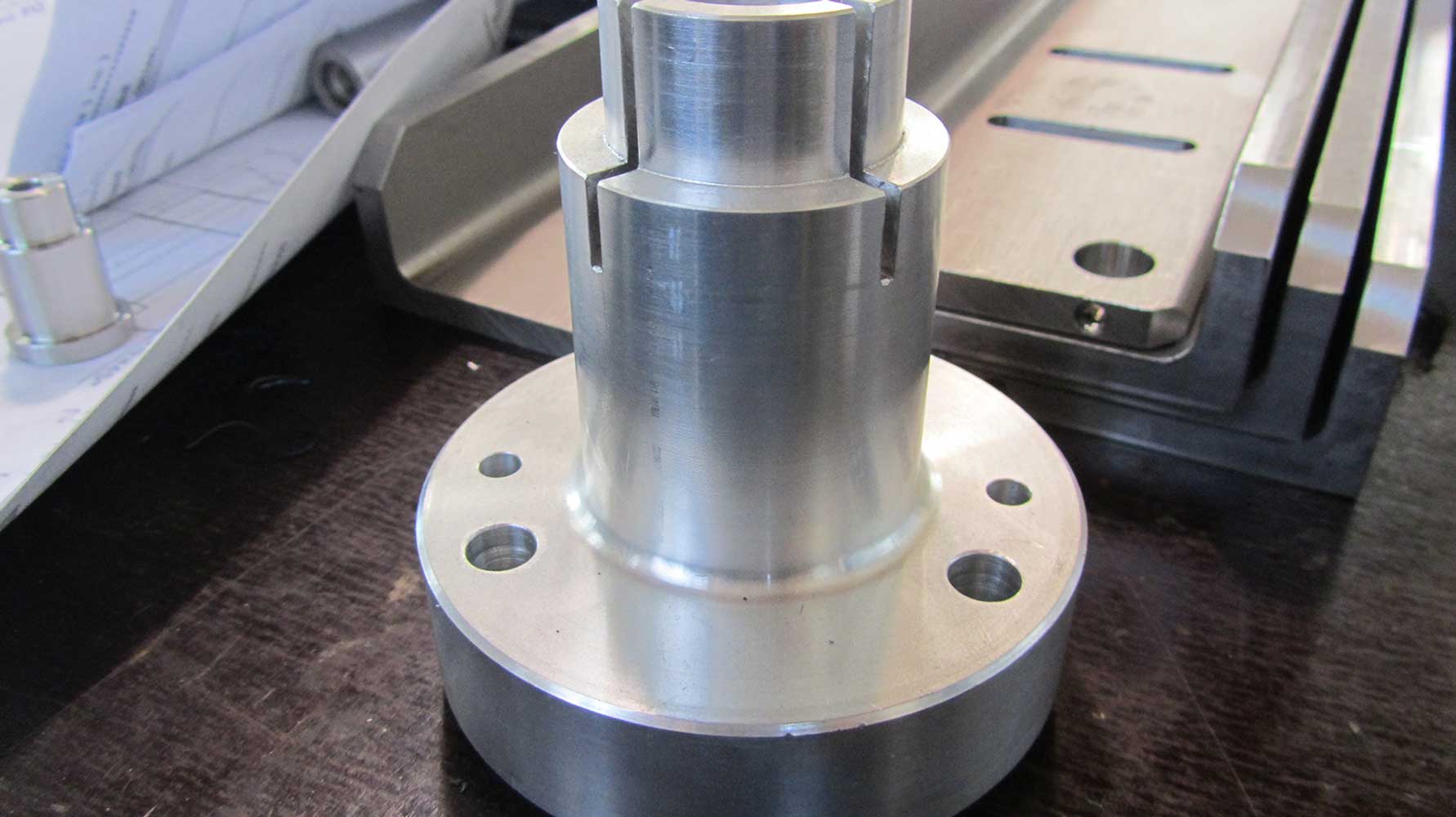

CNC MILLING

Computer-controlled machine tools are essential for the production of complex pieces requiring high precision. In the previous years, our professionals obtained great experience during the manufacturing of pieces requiring various and creative solutions. According to our opportunities, we strive to fulfil unique, as well as large orders.

CNC processing station:

NCT-EML 1020B 1020*550*600 – 1 piece

CNC lathe:

NCT-TNL 120 ALDT 250*250 – 1 piece

SHEET METAL MACHINING

Sheet metal bending is one of the most widespread shaping techniques, and it is an essential element of sheet machining processes. Obtaining the desired results during bending requires high precision and expertise. At our company, bending works are carried out with CNC-controlled and traditional metal bending machines. In addition, with the help our hydraulic and eccentric presses, perforation, punching and pressing processes can also be carried out. In addition to our plasma and laser cutting machines, we also have hydraulic scissors for cutting.

Benders:

3050 mm, 1350 KN- 1 piece

50 T X 2050 mm-1 piece

Hydraulic presses:

40T-250T-3 piece

Eccentric presses:

16T-250T-11 pieces

Hydraulic scissors:

6×3000 FGH630A SIMEROM-1 piece

12×3000 FG1030 SIMEROM-1 piece

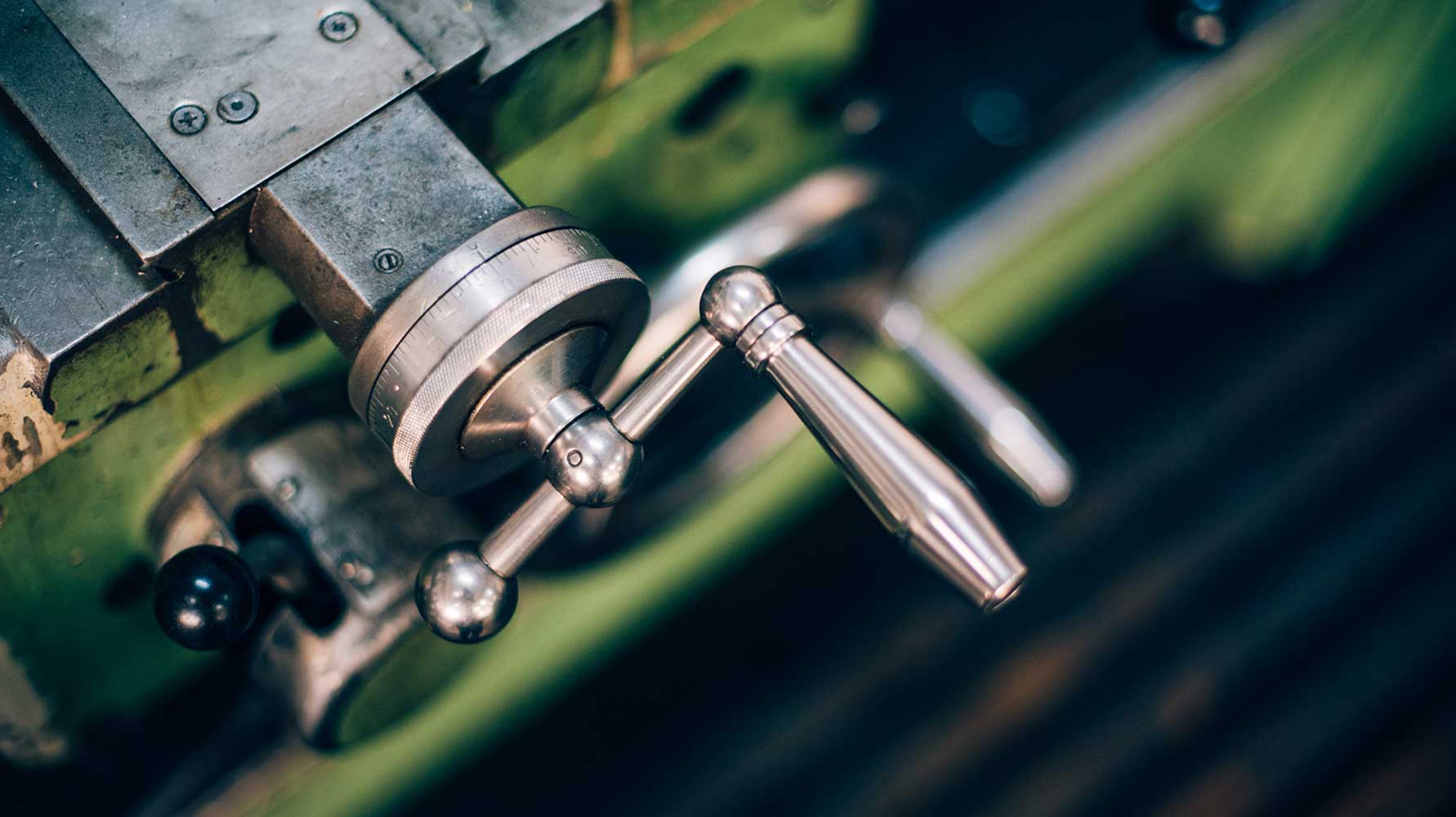

TRADITIONAL METAL WORKING

Our traditional metal working machinery and our decades of professional experience help us carry out creative and unique works which, from an economies of scale point of view, could not be carried out economically by using computer-controlled machines. In addition to traditional milling machines and lathes, we also have sawing machines suitable for cutting pipes and profiles, pipe benders, drills of different sizes and performances, as well as other equipment required to carry out a wide range of works.

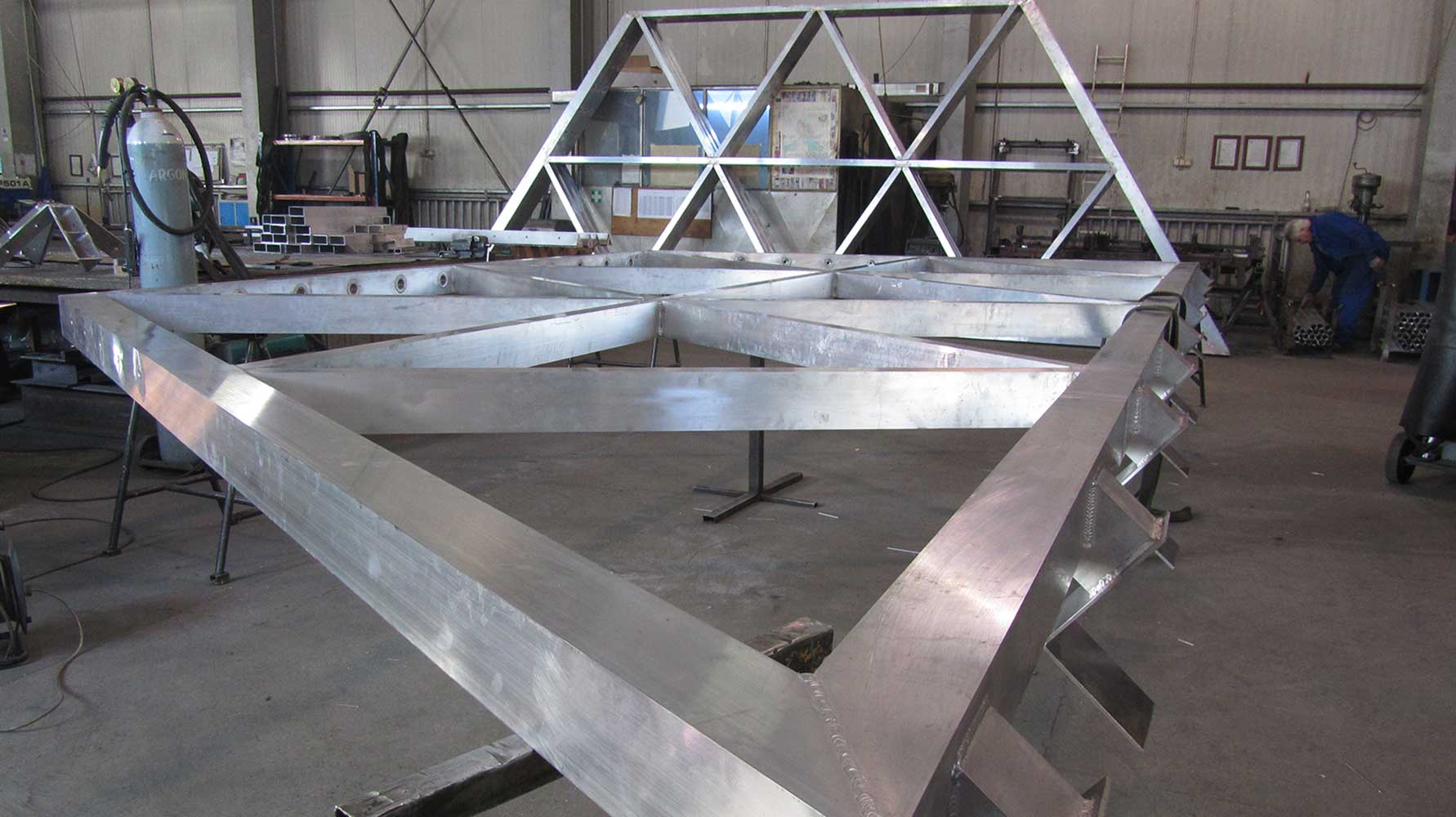

METALLIC STRUCTURE PRODUCTION

When it comes to manufacturing welded metallic structures, we have many years of experience. We are at our clients’ disposal, being able to carry out from the simplest to completely unique metallic structures. The metallic structures are manufactured at our location, based on plans provided by the client. In addition to the experience of our adept professionals, another great advantage is that we have our own cutting capacity to economically and rapidly prepare the plasma and/or laser cut, or bent prime materials necessary for production. The work of our welding professionals is carried out under continuous supervision by welding engineers, thus guaranteeing the products’ excellent quality. In accordance with client requests, the products’ surfaces can be treated with paint or via hot-dip galvanizing.

Română

Română Magyar

Magyar Deutsch

Deutsch